HN25HS Glass Microspheres

Product Specifications

| Attribute |

Value |

| Product Name |

HN25HS Glass Microspheres |

| Application |

Construction, Rubber, Aerospace Adhesives, Buoyancy Materials |

| Diameter |

25-85µm |

| Density |

0.15-1.0 g/cm³ |

| Compressive Strength |

750 psi |

| Chemical Composition |

SiO2, Na2O, CaO, MgO, Al2O3 |

| Color |

White or transparent |

| True Density |

0.244-0.256 |

| Bulk Density |

0.12-0.15 |

| Dielectric Constant |

1.2-2.2 (100MHZ) |

| Thermal Conductivity |

0.085 |

Hollow Glass Bubble Description

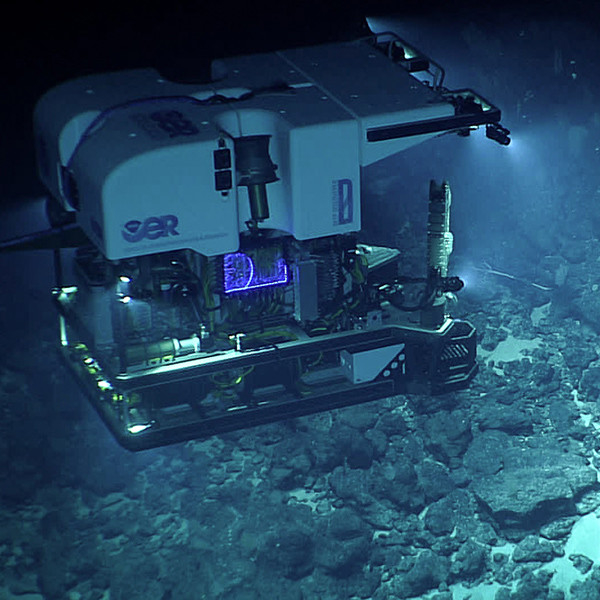

The theory behind using hollow glass bubbles in buoyancy materials involves reducing material density while maintaining or increasing buoyancy. The low density of hollow glass bubbles makes them ideal for reducing weight while preserving buoyancy properties.

Applications

- Underwater cables and pipelines: Provide buoyancy when wrapped around cables or pipelines, reducing weight and easing installation.

- Dredging and mining: Added to equipment to reduce weight and increase buoyancy, improving operational efficiency.

Technical Specifications

| Model |

True Density (g/cm³) |

Bulk Density (g/cm³) |

Compressive Strength (psi) |

Diameter (µm) |

| HN25HS |

0.23-0.27 |

0.13-0.16 |

500 |

25 (D10) |

70 (D50) |

105 (D90) |

Product Advantages

Light Weight

Enhance Stability

Anti Corrosion

Why Choose Us?

- Specialized in manufacturing Hollow Glass Bubbles for over 20 years

- Ranked among the largest HGB manufacturers globally

- Guaranteed product quality with comprehensive testing available

- Consistent product performance and reliability

Frequently Asked Questions

Can you tell me more about package details?

We offer carton and ton bag packaging options with dimensions varying by model and density. Customers can discuss preferred packaging plans with our team in advance.

For special requirements, we provide customized packaging solutions tailored to specific application needs.

What is Hainuo Technology's background?

Founded in 2011 with research backing from government institutions, we've achieved significant technological breakthroughs and now rank among the most competitive global manufacturers.

We've received national honors including "High-Tech Enterprises" and "Outstanding Enterprise in Shanxi province," with products used in major national oil and ocean projects.

What precautions should be taken when unpackaging?

Unpackage in ventilated areas, gently remove packaging bands, and control movement to minimize dust emission. Those with dust allergies should use protective equipment.

What are the advantages of hollow glass bubbles?

They enhance thermal insulation, fluidity, stiffness, strength endurance, and chemical resistance while serving as lightweight fillers.

What are common applications?

Widely used in aerospace, rubber, plastic, marine, and construction industries to improve performance and reduce production costs.

What is the density and size range?

Density ranges from 0.11-0.606 g/cm³ with sizes from 10-115µm, varying by application.

Are they environmentally friendly?

Yes, made from natural sand, recyclable, and produced with environmental responsibility as a core principle.

Can they be used in 3D printing?

Yes, they reduce weight and improve strength in 3D printing materials while enhancing printability and reducing warping.

Can they be used in concrete?

Yes, as lightweight aggregates they reduce concrete weight while improving thermal insulation, fire resistance, workability, and durability.

What is your production capacity?

Currently 15,000 tonnes annually, expanding to over 35,000 tonnes by 2026 with new production lines.

How should they be stored?

Store in dry, cool, dark areas away from moisture and direct sunlight. Keep packages tightly sealed to prevent particle emission.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!