BoyanCy Materials Sphericel Hollow Glass Spheres Micro Glass Bubbles HN32HS Thermoplastic

Product Specifications

| Attribute |

Value |

| Product name |

HN32HS Glass Microspheres |

| Application |

Construction, Rubber, Ocean |

| Diameter |

25-75µm |

| Density |

0.15-1.0 g/cm³ |

| Compressive Strength |

2000 psi |

| Chemical Composition |

SiO2, Na2O, CaO, MgO, Al2O3 |

| Color |

White or transparent |

| True Density |

0.314-0.326 |

| Bulk Density |

0.15-0.18 |

| Dielectric Constant |

1.2-2.2(100MHZ) |

| Thermal Conductivity |

0.108 |

Product Description

Hollow Glass Bubble Description

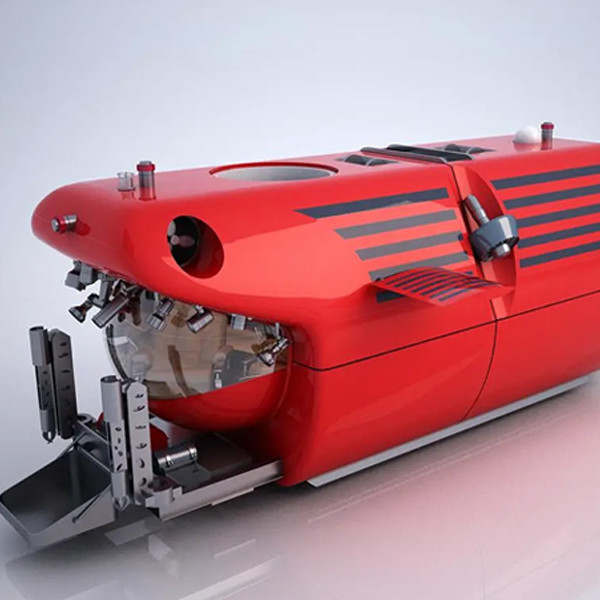

Buoyancy materials are extensively used in flotation applications for boats, docks, and other structures requiring long-term buoyancy. These materials must support the structure's weight while maintaining buoyancy, durability, and resistance to water and environmental factors.

The addition of hollow glass bubbles reduces material density while maintaining volume, resulting in lighter materials that provide the necessary buoyancy to support structural weight.

Hollow Glass Bubbles Applications

- Oil and gas exploration: Used in buoyancy materials to support equipment and instrumentation in offshore drilling and exploration activities.

- Recreational watercraft: Improves safety and performance of kayaks, canoes, and paddleboards by enhancing stability and control.

Technical Specifications

| Model |

True Density (g/cm³) |

Bulk Density (g/cm³) |

Compressive Strength (psi) |

Diameter (um) |

D10 |

D50 |

D90 |

| HN32HS |

0.30-0.34 |

0.15-0.18 |

2000 |

25-75 |

25 |

45 |

80 |

Product Advantages

Light Weight

Enhance Stability

Anti Corrosion

Why Choose Us?

- Specialized in manufacturing Hollow Glass Bubbles for over 20 years

- Ranked among the largest HGB manufacturers globally

- Guaranteed product quality with comprehensive testing capabilities

- Consistent product performance and reliability

Frequently Asked Questions

Can you tell me more about package details of Hainuo HGBs?

We offer carton and ton bag packaging options with dimensions varying by model and density. Customers can specify preferred packaging through advance contact with our team.

Custom packaging solutions are available to meet specific application requirements.

What is Hainuo Technology's history and achievements in HGBs?

Founded in 2011 with research backing from government institutions, Hainuo Technology achieved rapid technological breakthroughs to become a globally competitive manufacturer.

Recognized as a "High-Tech Enterprise" and "Outstanding Enterprise in Shanxi province," our products are used in major national projects by CNPC and CNOOC.

What safety precautions should be taken when handling HGBs?

Unpackage in ventilated areas with minimal vibration to control dust. Those with dust allergies should use protective eyewear and gloves.

What are the advantages of hollow glass bubbles?

They provide thermal insulation, improve fluidity and stiffness, enhance strength endurance, and increase chemical resistance while reducing weight.

What are common applications of hollow glass bubbles?

Widely used in aerospace, rubber, plastic, marine, and construction industries as lightweight fillers to improve performance and reduce costs.

What is the density and size range of Hainuo HGBs?

Density ranges from 0.11-0.606 g/cm³ with sizes from 10-115µm, varying by application requirements.

Are Hollow Glass Bubbles environmentally friendly?

Yes, made from natural sand, they are recyclable and cause no environmental harm, reflecting our commitment to sustainable production.

Can Hollow Glass Bubbles be used in 3D Printing?

Yes, they reduce weight and improve strength in 3D printing materials while enhancing printability and reducing warping.

Can Hollow Glass Bubbles be used in Concrete?

Yes, they serve as lightweight aggregates that improve thermal insulation, fire resistance, workability, and durability of concrete.

What is Hainuo's annual production capacity?

Current capacity is 15,000 tonnes annually, expanding to 35,000 tonnes by 2026 with our second production line.

What are the storage requirements for Hollow Glass Bubbles?

Store in dry, cool, dark areas away from moisture and direct sunlight. Keep packages tightly sealed to prevent particle emission.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!